I got the book, thank you very much!

I also got a knife from Werner, which he sharpened using your method. Indeed, there is no increase in the cutting force with the number of cuts to cut the BESS thread with the knife. He also gave me a couple of Feather razor blades. These were not better than Wilkinson razor blades in my tests and again showed an increase in cutting force with the number of cuts ...

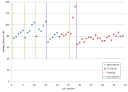

I usually sharpen knives with a cutting edge angle of more than 40° (more than 20 dps). But now I wanted to see which sharpness I can achieve and ordered a Viktorinox "flower knife" (little and easy to sharpen). I sharpened this with a 20° cutting edge angle. The measurement results are:

At the second position I finally saw a micro-dent after cut 28 that looks similar to your last picture in post #9 :-)

But nothing can be seen at the other positions, although the cutting force increases.

> BESS test line diameter is about 0.22mm, and under the same load it exerts

> more pressure per point, than the fishing line of 0.25mm diameter.

I had ordered fluorocarbon fishing line with 0.25 mm, as my measurement on the BESS thread showed 0.24 - 0.25 mm. In fact, according to my measurement, the fluorocarbon line is 0.26 mm. This should not be due to the caliper, as it shows the correct values with feeler gauges.

I also got a knife from Werner, which he sharpened using your method. Indeed, there is no increase in the cutting force with the number of cuts to cut the BESS thread with the knife. He also gave me a couple of Feather razor blades. These were not better than Wilkinson razor blades in my tests and again showed an increase in cutting force with the number of cuts ...

I usually sharpen knives with a cutting edge angle of more than 40° (more than 20 dps). But now I wanted to see which sharpness I can achieve and ordered a Viktorinox "flower knife" (little and easy to sharpen). I sharpened this with a 20° cutting edge angle. The measurement results are:

At the second position I finally saw a micro-dent after cut 28 that looks similar to your last picture in post #9 :-)

But nothing can be seen at the other positions, although the cutting force increases.

> BESS test line diameter is about 0.22mm, and under the same load it exerts

> more pressure per point, than the fishing line of 0.25mm diameter.

I had ordered fluorocarbon fishing line with 0.25 mm, as my measurement on the BESS thread showed 0.24 - 0.25 mm. In fact, according to my measurement, the fluorocarbon line is 0.26 mm. This should not be due to the caliper, as it shows the correct values with feeler gauges.